Wire EDM (Electrical Discharge Machining)

Wire EDM

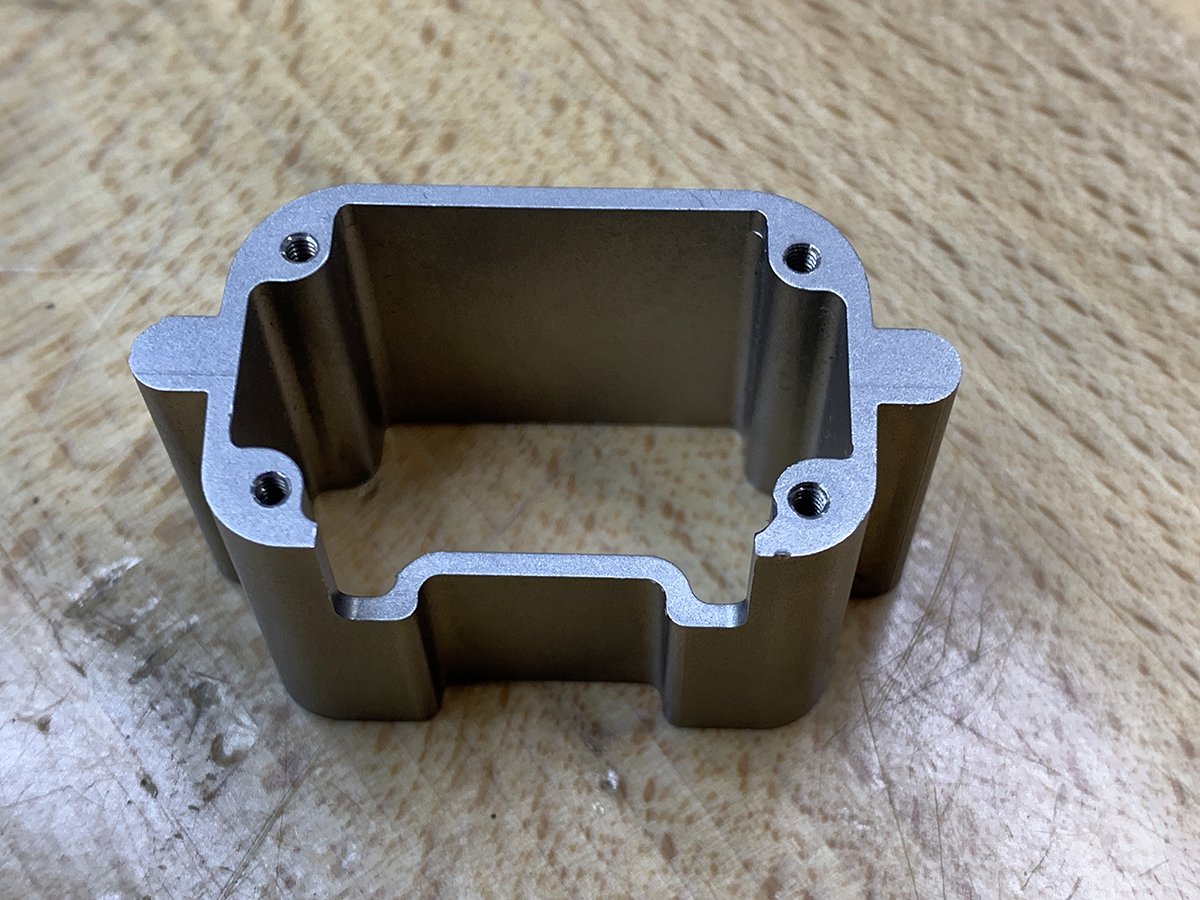

Wire EDM uses an electrically charged hair-thin wire to machine components out of conductive workpieces. Machining complex shapes or those with tight tolerances can be nearly impossible with conventional machining techniques. At LG Metalworks, we can easily make precise cuts and intricate components with a Wire EDM process.

How WIRE EDM Works

Instead of a cutting blade like a band saw, Wire EDM uses an electrically charged hair-thin wire and a conductive workpiece grounded to the machine table. When the two conductive pieces get close, a white-hot spark jumps the gap, melting away dust-sized particles. With Wire EDM, the wire and the workpiece never actually touch. The spark does all the cutting. Deionized water acts as a cooling medium, controlling the sparking and flushing away tiny metal particles.

Benefits and Capabilities

Wire EDM allows intricate geometric cuts on parts nearly impossible to accomplish with traditional methods.

Wire EDM can be used to cut delicate parts that would likely get damaged by traditional mill or lathe work.

LF Metalworks can cut a variety of metals with Wire EDM, including PCD (Polycrystalline Diamond).

LG Metalworks can make super precise cuts with wire sizes from .01 to .004

Wire EDM Materials

Aluminum

Brass

Copper

Exotic Metals

Molybdenum

Titanium

Tungsten

Tool Steels